Control and monitoring – these are basically standards that are part of every domestic task program in agriculture. In every yard – regardless of its size – there are already innovative technologies that need to be controlled and monitored: conveyor equipment and storage, cleaners and dryers, mills and mixers. The more networked they are and communicate – with each other and with the farmer, the more benefits of the systems. It is not enough to keep an eye on it here and there and quickly press one or more buttons. So that everything really runs smoothly, you need sophisticated software programs, smart monitoring and controls that simply master the complex processes.

Complex tasks

Now it is certainly not a problem to manually start or stop a screw conveyor or cleaner. During the drying process, the moisture is checked to prevent blowing too much money into the air.

If you produce your own feed mixes, you have to reset the mill depending on the grain type, enter the recipe for mixing, dose mineral and oil additions – and transport all of this from different bins to milling and mixing system, and then conveying it to animal feed silos.

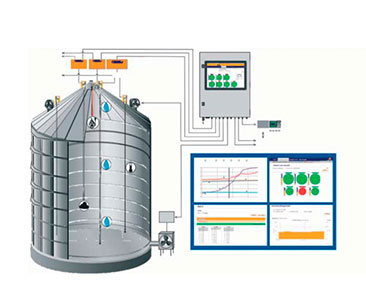

And then you still have to constantly take care of quality assurance of the stored goods: check the temperature and humidity to prevent pest and fungus infestation, if necessary, to counteract this with ventilation and cooling.

In most companies, all of this has to happen not only without major delays, but often simultaneously! And as if that weren’t enough, all of this must also be documented for quality control.

All bases covered!

Of course, this can be done manually with appropriate amount of time. But you don’t have to! NEUERO helps you to control and monitor these operational processes. And – for the potential smart farmers among you – to put all of this on a digital basement.

For this purpose, NEUERO has developed its own control systems for all relevant areas: up to date, innovative, reliable, simple and easy to use individually or fully automatically for the entire yard. Among other things, we offer you:

- VARIUS – an automatic PLC control system for conveyor equipment and dryer. You control from the touch display, simply entering what should be conveyed, from where to where – and that’s it. This control system also operates the elevator dryer fully automatically.

- EASY mill control system provides comfortable control over milling of 4 grain components maximum in 4 storage silos maximum. Empty and Full Sensors can be integrated for fully automatic filling of the silos.

- CIBUS milling and mixing computer due to which a complete grain system can be controlled – from grain conveyance to storage, from ventilation, milling, feed mixing, to flour and feed conveyance via pipe-type chain conveyor into the barn. It also offers every opportunity to meet the required documentation requirements.

These are just three examples of our own control system. Of course, our employees will tailor and program the systems to your individual needs. We have our own department for planning, production and programming of control systems, which is always at your side.